ASOURCE®TIMES

COVID-19の拡大に伴って、医療物資の保護貿易的な方針が各国で採られている。

わが国は、経済成長を続けるアジア諸国と互恵的な発展を唱え、医療物資の国際分業を加速してきた。

しかし、COVID-19の世界的蔓延は、医療物資の流通に大きな影響を与え、

国内供給が途絶える危険性があることを露呈させた。

※2020年6月の状況を反映

2019年12月に中国の武漢において初めての感染者が確認されたCOVID-19は瞬く間に中国からアジアへ広がり、その後はアジアを超えて欧州や米国に侵入し、感染を急速に拡大させた(国立感染症研究所より)。現在ではアフリカ・南米でも患者が急増しており、北米・欧州と比べて人口が多いことや、医療体制の状況から、さらなる感染拡大が憂慮される事態となっている。

このような強力な感染症への対策を打つ上で最も重視されるべきは、人的流れを遮断することである。中国やインド、イタリア、スペイン、米国などの主要都市で講じられた都市封鎖(ロックダウン)はその最たるものである。それらの地域では感染拡大の抑止効果が見られ、流行の発火点とみられる武漢ではロックダウンをいち早く解除した。

しかし一方で、そのような強硬な封じ込め政策は、広範な経済活動の停滞をもたらしている。国際通貨基金(IMF)が2020年4月14日に発表した経済見通しによると、COVID-19の拡大によって、2020年の経済成長率は前年比3%減になるという。各国経済が過去数十年で最も早いペースで縮小しており、「1930年代の世界恐慌以来で最悪の景気後退に直面する」とIMFは警鐘を鳴らしている。

新興感染症が世界を席巻するという状況下では、単に人的な交流や物流の停滞、経済活動の低下がもたらされるだけでなく、自国民の生命を最優先するとの考えに基づき、生命維持に関わる医療物資について保護貿易的な方針を多くの国が採る事態になっている。

『ニューズウィーク日本版』(2020.4.28号)はCOVID-19の感染が拡大した結果、人工呼吸器やマスクなど医療物資の国際的なサプライチェーンが危機に瀕していると報じている。同誌によると、「英仏など54の国と地域が年初から一部の医療物資の流通を制限し、3月だけで新たに70品目の輸出規制がなされた」という。

こうした情勢を受け、安倍晋三首相は4月15日、経団連の中西宏明会長ら産業界トップに医療物資の増産対応を要請した。このとき、同首相は「新型コロナウイルスとの闘いで重要な物資の生産、サプライチェーンは国内で確保しなければならない。人工呼吸器は1万5000台まで確保済みであるが、2万台に増やしたい」と発言している。それと並行してASEAN諸国とも協議し、医療物資の日本への提供も呼び掛けている。さらに、2020年度補正予算・緊急経済対策では、医療機器の増産支援の名目で、88億円の予算を確保した。

また、厚生労働省の対応として、医政局経済課は2月4日に、日本医療機器産業連合会、米国医療機器・IVD工業会、欧州ビジネス協会医療機器・IVD委員会の3つの業界団体に対し、中国から輸入している医療機器もしくは原材料等について在庫状況、今後の製造見通しなどを確認し、安定供給のために必要な措置を講じるよう連絡した。4月3日には同省生活衛生局医薬品審査管理課、同医療機器審査管理課が「新型コロナウイルス感染症対策における人工呼吸器などの更なる確保・増産に向けて薬事規制における取り扱いを明確化する方針」を示し、これによって医薬品、医療機器、体外診断用医薬品、再生医療等製品の承認審査の迅速化を表明した。

このように政府は医療物資の海外依存への危険性を感じ、国内安定供給の万全を期するため様々な対応を行っている。

実際、医療機器の輸出入を見てみると、国内市場規模2兆8,870億円のうち輸入額は1兆5,564億円で、輸出額5,840億円との差額は9,724億円に達し、この傾向は現在も続いている。また、平成23〜28年までの年平均成長率は輸出額が4.0%であるのに対して輸入額は8.0%と輸出額の2倍の速度で輸入額が伸びている。(平成28年度 薬事工業生産動態統計より)

ただ、わが国の医療機器がおしなべて輸入に依存しているわけではなく、その種類により強弱がはっきりしている。内閣官房健康・医療戦略室が作成した資料によると、医用X線CT装置、臨床化学検査機器、血液体外循環機器、医用内視鏡などは、日本企業のシェアが高く、海外にも輸出している。

対照的に日本企業のシェアが低く、海外製品の輸入に依存している製品群は、手術用電気機器および関連装置、結紮・縫合用器械・器具、生体内移植器具、生体物理現象検査用機器、磁気共鳴画像診断装置などだ。特に今回、医療現場で不足が問題視されている、医療用マスクや医療ガウンなどのPPEや人工呼吸器の大半は海外製品で、国内増産の余地が小さいとの懸念が以前から指摘されていた。

とはいえ、医療物資の国内増産には課題も多い。例えば人工呼吸器は、その製造に約200点にも及ぶ部品を必要とするため、今回のような事態下では増大する需要に製造が追いつかなかいことも想定される。だからといって安易に部品製造業者を変えることもまた難しく、信頼性と安全性の保障が確保できるかどうかの検証を含め、新たに厚生労働省の承認を得るためのコストや時間がかかる。また、医療物資の国内増産はそれだけで価格の高騰に繋がるため、さらに医療機関の財政的負担を増加させるという側面もある。

このように、医療物資の国内増産を進めたい政府や、医療物資を製造する企業、実際に医療物資を使用する現場とで感じている問題点が違うため、医療物資の国内増産について是非が問われている。

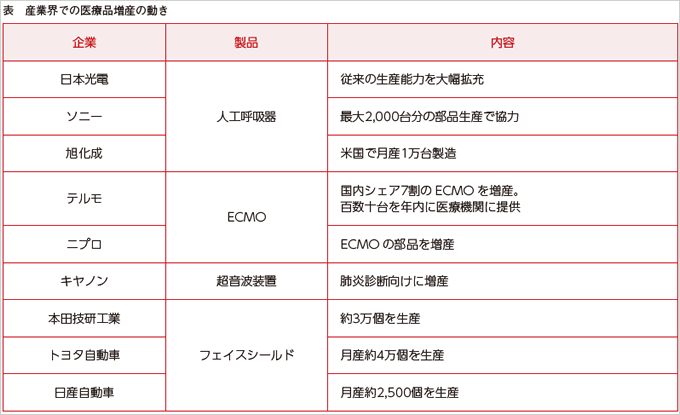

しかし、「売れ残るようなら備蓄として買い上げる」と国が表明したことが追い風となり、産業界では医療物資の増産が進んでいる(表)。

日本光電は群馬県の工場で生産しているマスク型の人工呼吸器を、従来の年間360台程度から今後6カ月以内に1,000台の供給を目指す方針を明らかにしている。ソニーは厚生労働省が審査の簡素化の方針を固めたことを受け、人工呼吸器の部品の増産を表明、早ければ7月に1,000~2,000台分の生産協力を始める。

テルモは静岡工場で進めていた体外式模型人工肺(ECMO)を増産、従来の1年分に相当する生産を数カ月で行う。キヤノンも肺炎診断向けの超音波装置を増産、ホンダは車体部品の設計用だった3Dプリンターを活用して短期間でフェースシールドを生産、医療現場に提供することを表明するなど、今回の事態を受け、各企業が医療物資増産へ積極的に取り組んでいる。

ただ、COVID-19の感染者数が減少し始めた現在では医療物資の過剰生産・過剰輸入に繋がらないように増産計画を修正することも必要だろう。今回のCOVID-19の感染拡大で明らかとなったパンデミック時の医療物資の対応について、国内においては、輸入と国産のバランスを考えた生産拠点の多元化や備蓄の大幅強化など、医療機器業界全体で製造・供給体制のさらなる見直しが求められている。